MACHINING

At Chicago Gasket Company, we are established industry experts in the machining of PTFE and plastics as well as molding and extruding. We combine high quality with high volume capacity that can directly answer your commercial or industrial needs. Backed by comprehensive experience, our services are featured in many industries, stretching from aerospace and automotive to medical and military.

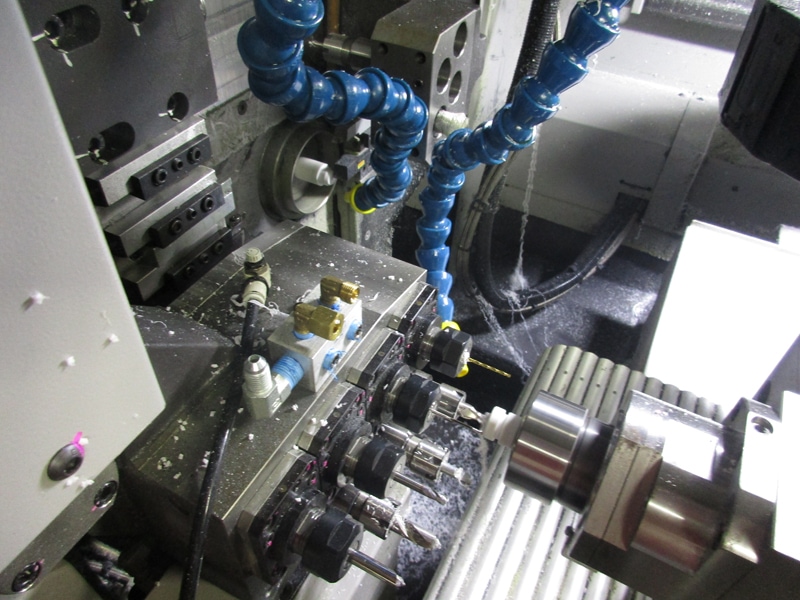

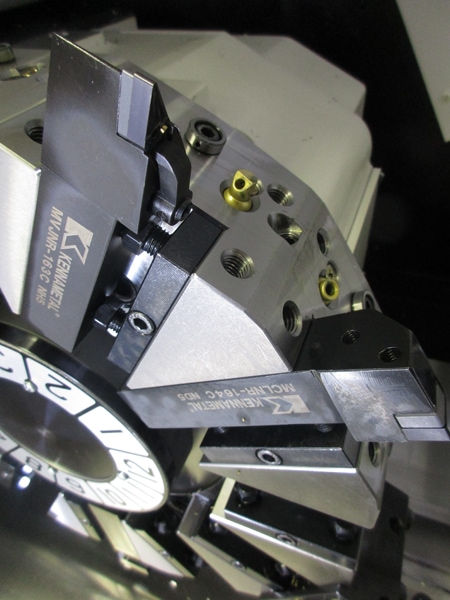

Our CNC machining capabilities are geared for the production of complex parts with tight tolerances. Thanks to our CAD-enabled CNC approach, we can render low to high volume production runs with cutting-edge precision and speed. Furthermore, by using our own molded or extruded basic shapes, such as rod and tube, a broad range of machined parts can be produced quickly and easily.

Our primary machining facility covers many processes including: milling, drilling, boring, turning for contour or forms, and internal/external threading. Major equipment assets include our main 2 & 3 axis CNC Lathes, 6-axis swiss turning up to 1.250″ (32mm) as well as a 37″ outer diameter swing lathe, and complete manual milling facilities. Secondary systems include automatic screw machines, turret lathes, engine lathes, drill presses, centerless grinders, punch presses, and a number specially designed systems for specific processing & fabricating requirements.

No matter your particular challenge or need, our comprehensive array of CNC machining capabilities can provide the exact precision and tolerances your applications require.

For more information on our CNC Machining services, feel free to contact us directly.

| CNC MACHINING HIGHLIGHTS | |

|---|---|

| Machining Processes | Milling Drilling Boring Turning:

|

| Equipment Capabilities | CNC Control Capabilities Large Swing Lathe (up to 37" Outer Diameter) Bar Feed Milling CAD Design Services (AUTO CAD/SOLID WORKS) Reverse Engineering |

| Machinery Axis | CNC Turning up to 6-axis with live tool/milling |

| Part Diameter | Up 37" OD |

| Materials | PTFE (Virgin & Filled) Fluoropolymers All Engineering Plastics

|

| Materials (Other Materials) | Phenolic Other Non-Metallic Material Upon Request |

| Production Volume | Prototype Low Volume Production Runs High Volume Production Runs |

| Additional Information | |

| Industry Focus |

|

| Intended Applications |

|

| Industry Standards | ISO 9001:2015 |