COMPRESSION MOLDING

At Chicago Gasket Company, we specialize in manufacturing high-quality custom molded parts for a wide range of demanding industries. Our reputation for quality and value has made us a go-to supplier for many commercial and industrial firms. We also provide outstanding flexibility in manufacturing capabilities; this ensures that the best methods for your particular application are used. Our diverse customer base relies on us for made-to-order compression molded products.

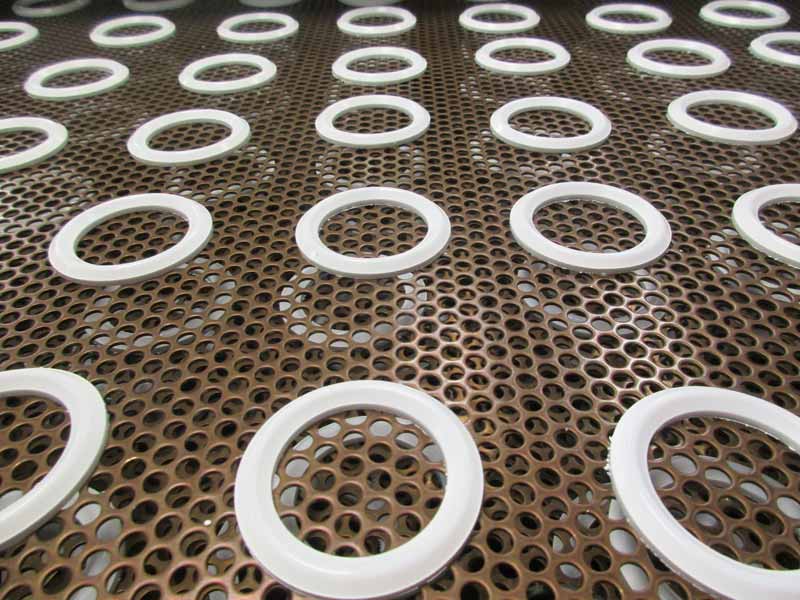

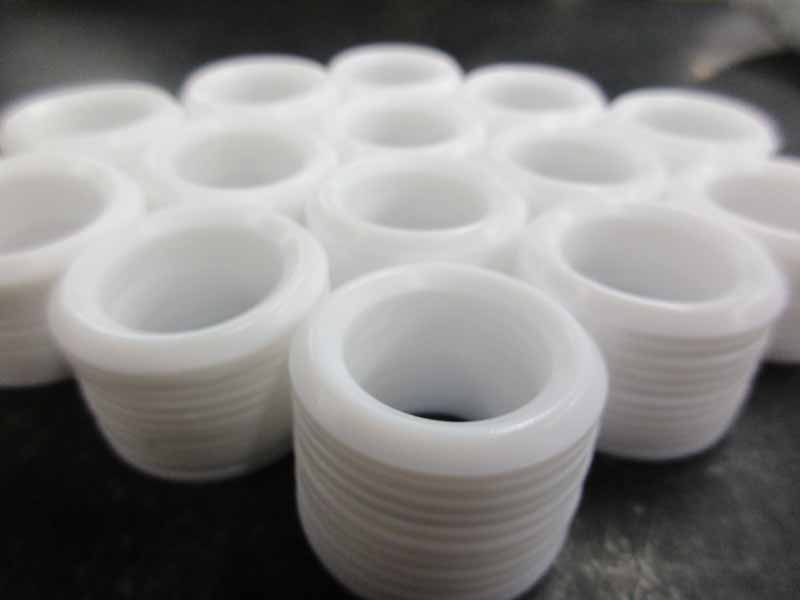

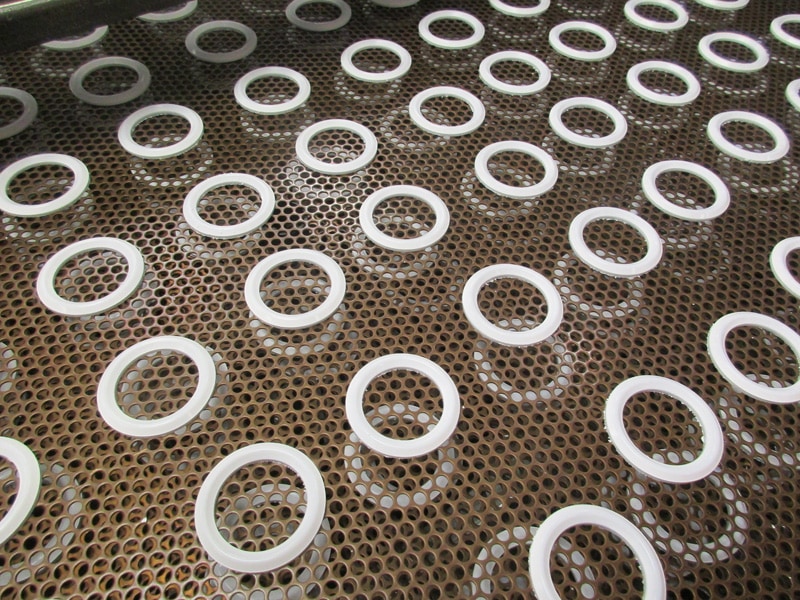

For PTFE parts in medium to large quantities, compression molding on our high-speed automatic machines proves to be the most efficient and economical manufacturing method. We can also incorporate the insert molding process for additional design flexibility. Compression molding is ideally suited for manufacturing of products such as V-rings, disks, ball valve seats, seals, semi-finished shapes, flat rings, poppets, and much more. Compared to traditional machining, compression molding provides a solution at a fraction of the cost while still holding reasonable tolerances.

In addition to compression molding, we can also provide many value added services to enhance the design and development process. These include rapid prototyping, engineering & design consultation, CAD/CAM, standard prototyping, and test samples. No matter the design consideration or complexity challenge, our ISO 9001:2015 certified molding services can boost your bottom line without compromise. We invite you to see what we can do for you today.

For more information about our compression molding capability, feel free to contact us directly.

| COMPRESSION MOLDING HIGHLIGHTS | |

|---|---|

| General Capabilities | Made to Customer Specifications Prototyping |

| Molding Process | Compression Molding Insert Molding |

| Molded Product |

|

| Additional Services Provided |

|

| Production Volume | Typical Run Quantity are above 1,000 units Single and Multi Cavity Process Allows Low Volume High Volume |

| Additional Information | |

| Industry Focus |

|

| Industry Standards | ISO 9001:2015 (pending) International Organization for Standardization |